Offshore pipeline installation is the next step after designing. These days, there are few methods that commonly used and can be adapted to install offshore pipeline system, such as S-Lay method, J-Lay method, Reel Barge, and Beach Pull.

S-LAY METHOD

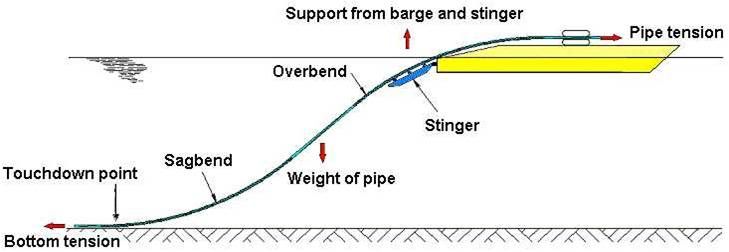

This method is quiet time-saving and can be done in vary depths. S-Lay refers to the pipeline shape forming “S” during the installation. This method requires lay-barge or other vessel designed to pipe-laying. Pipe is eased off the stern of the vessel as the boat moves forward. The pipe curves downward from the stern through the water until it reaches the seafloor. As more pipe is welded in the line and eased off the boat, the pipe forms the shape of an “S” in the water. Stingers, measuring up to 91 meters long, extend from the stern to support the pipe as it is moved into the water, as well as control the curvature of the installation. Some pipe-lay barges have adjustable stingers, which can be shortened or lengthened according to the water depth.

In S-Lay method, pipe receive more stress, especially at the bending (curve). This may become a concern due to pipe-cracking.

J-LAY METHOD

J-Lay method put less stress on the pipe during installation, since there are only one bend (curve) forming the shape of “J”. This method inserts the pipeline in an almost vertical position. Pipe is lifted by a tall tower on the boat/barge, then inserted into the sea. The pipe bends once, under the water, taking on the shape of “J”.

REEL LAY METHOD

This method is firstly proposed to install pipeline with relatively small in diameter. But it have been developed to install pipeline with 12″ to 16″ diameter in size. This method used coiled pipe on a spool (reel) resulting in fast productivity due to the ability to lay the pipe by “unwinding” it from the reel. The process costs due to the reduced number of personnel required to lay the pipe, lowering the risk of accidents at the same time, and providing efficiency in the availability of the pipe.

Each reel is designed to operate with a specific barge and can usually handle pipe from 2″ to 12″. The total length capacity depends on the spool dimensions and the diameter of the pipe.

BEACH PULL METHOD

Beach pull or also known as shore pull method is adapted for a near-shore pipe installation that is perpendicular to the shoreline, with pulling pipeline from the shore. Pipe is welded on a lay barge where the end of the pipe to shore set with pull head. Pull head hooks cable from shore.

The cable is connected to a winch on shore. Pulled pipe then glided into water through its route. Each segment of pipe is completed with buoy. When all pipes are on they’re position, buoys then being released.

Source : http://www.kartmarine.com

No comments:

Post a Comment